Humidity control is crucial in textile processing, especially in garments packaging rooms. Improper humidity can damage machines, halt production, and affect product quality. As a trusted provider of dehumidifier solutions for garments packaging rooms, we help businesses improve product weight, quality, and machine efficiency.

Textiles are hygroscopic, meaning they absorb or release moisture based on the surrounding air’s relative humidity. To maintain ideal conditions, investing in a garments packaging room dehumidifier is essential. Our dehumidifier solution for garments packaging room ensures effective humidity control in textile packaging, while providing reliable garments packaging area humidity control. With the rise of smart technologies, dehumidifiers for the garments industry are becoming indispensable for maintaining consistent quality in Bangladesh’s growing textile sector.

Garments products collect and release moisture based on the relative humidity of the ambient air. This process, known as garment packaging dehumidification, is crucial for maintaining product quality. If the environment is drier than the textile’s equilibrium relative humidity, the textile will lose moisture to the surrounding air. On the other hand, excessively humid air causes the material to absorb more moisture, potentially leading to damage.

The moisture gain-loss cycle is unavoidable throughout the life cycle of garments, from manufacturing to usage. However, using a dehumidifier solution for garments ensures textiles retain their necessary qualities. Proper humidity control for garments packaging reduces the growth of fungus, mold, and mildew while preventing foul odors. As a leading garments dehumidifier provider, we offer advanced solutions like the garment packaging humidity controller to maintain an ideal environment, protect garments, and avoid damage during storage or shipment.

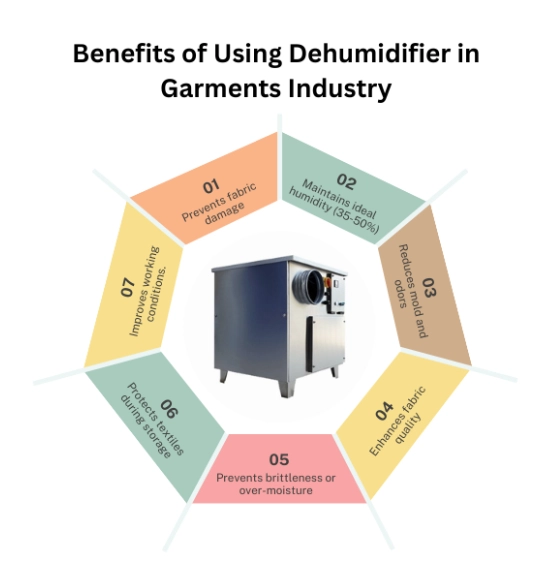

Managing humidity effectively is crucial for garment packaging and storage. Here are the key benefits of using dehumidifiers:

Proper garments packaging room humidity management ensures textiles maintain their strength, flexibility, and moisture balance. This prevents defects and keeps fabrics durable during production and storage.

Dehumidifiers in textile packaging rooms lower lint, dust, and particulates, creating a cleaner workspace. This protects garments from contamination and ensures a healthier environment for workers.

Installing a garments packaging facility dehumidifier helps save energy while improving cooling efficiency. Cold water systems can reduce ambient temperatures, creating a more comfortable workspace.

Effective garment packing area dehumidification provides better air quality and reduces humidity-related discomfort. This improves employee satisfaction and enhances overall productivity.

Prevent damage caused by excess moisture in storage and packaging areas. Contact us for more details.

Garments naturally absorb and release moisture based on the surrounding air’s relative humidity. When the air is drier than the textile’s equilibrium relative humidity, the fabric releases moisture, and when it’s too humid, the material absorbs more. These fluctuations in moisture can significantly impact the fabric’s properties, such as tensile strength, elasticity, and fiber diameter. Maintaining optimal garments packaging room humidity control with the use of a dehumidifier for garments packaging room is crucial to prevent the textiles from becoming brittle, weak, or over-moisturized, which can lead to damage during processing. The dehumidification process ensures the textile remains in an ideal environment, promoting better fabric quality.

Using a garments packaging facility dehumidifier helps maintain the proper relative humidity levels (35-50%) and temperature, which allows fabrics to release excessive moisture and prevents the negative effects of moisture gain-loss. Garment packing area dehumidification also reduces the growth of mold, mildew, and unpleasant odors, thus protecting the fabrics and improving working conditions. For a controlled garment packaging warehouse dehumidifier setup, textiles are stored in a moisture-controlled space that reduces damage and enhances product quality, ensuring your textiles are preserved in the best possible condition.

Dehumidifiers are essential in manufacturing and processing rooms to maintain optimal moisture levels in textiles. Excess moisture during weaving, dyeing, or finishing can weaken fabrics, causing them to lose tensile strength and elasticity. Garments dehumidifiers in processing rooms help maintain consistent moisture levels, ensuring fabrics stay durable and flexible.

Proper humidity control in garment packaging rooms is critical to prevent damage to garments before shipping. Dehumidifiers help reduce the risk of wrinkles, mold, or mildew by maintaining an ideal moisture level. This ensures the garments remain in pristine condition during packaging and storage.

In storage areas or warehouses, textiles can be damaged by excessive moisture, leading to mold growth or fiber degradation. Garment packaging warehouse dehumidifiers help regulate humidity, ensuring textiles stay in optimal condition, preserving their quality until they are ready for distribution.

During transit, garments are exposed to fluctuating humidity, which can affect their quality. By using garment packing area dehumidification, moisture levels can be controlled, preventing damage such as mildew or color fading, ensuring the garments reach their destination in top condition.

As a trusted Garments Dehumidifier provider, we offer the best Dehumidifier solutions for Garments to ensure optimal moisture control in your garment packaging rooms. Our specialized Garments packaging room dehumidifier systems are designed to protect your textiles from damage caused by fluctuating humidity. Whether you’re in the textile manufacturing or garment packaging industry, our Dehumidifier for Garments Industry ensures that your products stay in pristine condition throughout production, storage, and shipment. Choose us for reliable, efficient and customized dehumidifier solutions that enhance your product quality and protect your investment.

Let us help you maintain ideal humidity levels in your garment industry.

Dehumidification is essential in a garments packaging room humidity management process because it helps maintain the right moisture levels. This prevents fabrics from absorbing excess moisture or losing too much, ensuring the garments stay in top condition during storage and packaging.

Garment packaging room dehumidifiers control moisture levels within the packing environment. By reducing excess humidity, they prevent the textiles from becoming brittle or too loose, preserving their strength, flexibility, and overall quality.

The best industrial dehumidifiers for garment storage are those designed to efficiently manage humidity levels in large-scale operations, such as garment packaging warehouse dehumidifiers. These systems are powerful enough to maintain consistent moisture levels, protecting garments from humidity-related damage.

Yes, dehumidifiers for textile packaging rooms can be used across various areas of the garment facility, including storage rooms, packaging areas, and production lines, to maintain optimal humidity levels. This ensures that the textiles remain in perfect condition throughout their lifecycle.

Selecting the right dehumidifier solution for garments depends on the size of your facility, the type of textiles you handle, and the specific humidity control needs. Our experts can help you choose the best solution tailored to your garment packaging facility dehumidifiers and environmental conditions.

Garment packing area dehumidification ensures that the textiles remain free from excessive moisture or dryness, preventing damage such as fabric shrinkage, warping, or weakening. It also helps reduce the risk of mold or mildew formation during storage.

Routine maintenance is essential to ensure that your garments dehumidifier in Dhaka operates efficiently. Typically, dehumidifiers should be serviced every 6 to 12 months, depending on the level of use and environmental conditions.